Battery development is getting smarter

After 2035, the EU will ban selling diesel and petrol-powered cars, accelerating the transition toward zero-carbon transformation. Electric vehicles are in insane demand, and at present, batteries are the most reliable way to store electricity for these vehicles. As electric cars become more popular, batteries must last longer and store more energy in a smaller volume and mass. Battery capacity should remain at least 90% of its initial storage capacity after 1000 cycles of charging and discharging, according to USABC targets.

Generally, Lithium-ion batteries take a long time to test. For example, Charging the battery at a high rate, such as 3C, takes about 20 minutes. Therefore, the process of charging and discharging the cell for 1000C will take a month to complete. Moreover, thousands of tests are required to optimize a parameter and achieve a result.

Nevertheless, by using artificial intelligence (AI) and machine learning (ML), the battery industry can greatly reduce the time it takes to test batteries. Models using AI and ML can predict battery behavior based on the results of the first few charge/discharge cycles, reducing the time required for battery development, as well as optimizing conditions such as working temperature, battery components, and current rate. These methods can also be used to optimize the microstructure and electrochemical performance of battery active materials. Additionally, real-time data from an electric car's batteries can be monitored. Battery the state of health (SOH) and its remaining life are estimated by algorithms using ever-changing parameters of a vehicle, including its speed, temperature, and state of charge.

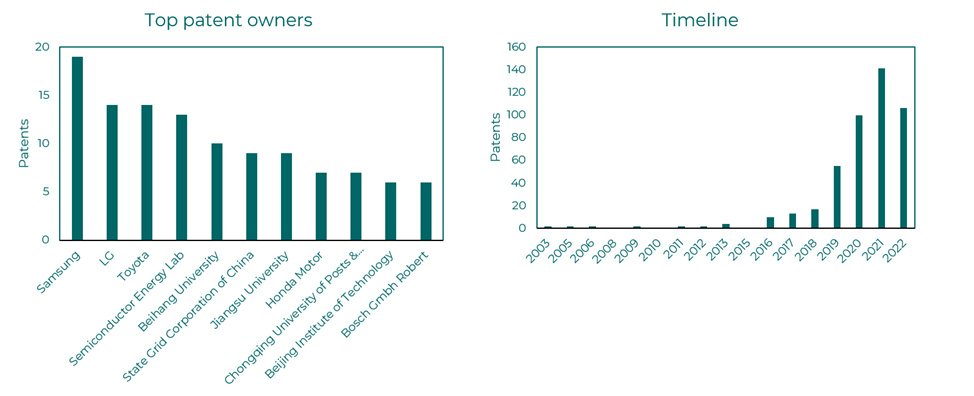

Patent analysis is conducted by BattScout shows a booming increase in patent registration from 2016 until now, from less than ten patents to more than a hundred patents a year. Samsung and LG Energy Solutions, both top lithium-ion battery manufacturers, are among the top companies in AI/ML patent portfolios. Toyota started collaborating with Stanford University and MIT in 2019 to predict battery performance using AI/ML. Moreover, Their technology is being followed by Jiangsu University, Honda Motor, and Bosch. Additionally, NREL has a project section called CAEBAT (Computer-Aided Engineering for Electric-Drive Vehicle Batteries), which reduces battery development costs and provides extremely fast charging through machine learning for the U.S. Department of Energy.