Conversion of Greenhouse Gas (CO2) to Plastic

In the past 40 years, intensive research has been conducted on the catalytic reaction of carbon dioxide to produce polymers. The disposal of carbon dioxide captured at the plant and the byproduct gas, methane, is a problem. Using captured carbon dioxide to reduce carbon emissions and produce raw materials for plastics (polycarbonates) is an up-to-date and economic issue. In the carbon reduction process, improving the durability and performance of catalysts is one of the challenges.

An increasing number of requests are being made to find ways to capture and sequester carbon from the atmosphere. For example, carbon is captured by engineered algae ponds in the desert, which is one method of removing environmental greenhouse gases. Seaweed restores coastal areas and sinks carbon to the ocean floor. As a result, these methods pose ecological concerns. From there, the blooms are harvested, the carbon-containing material is dried in the sun, and then the biomass is buried several meters into the ground. There have been previous failed attempts to convert lab-grown algae into profitable biofuels.

As a carbon dioxide capture and utilization technology, DRM (Dry Methane Reforming) reduces carbon dioxide production by more than 50% while producing plastic raw materials (such as polycarbonates). In Korea, LG Chem commercialized DRM facilities using proprietary technology processes and catalysts for the first time. The rapid degradation of catalyst performance has made commercialization of DRM challenging up to now. Nevertheless, LG Chem's catalysts were significantly more durable.

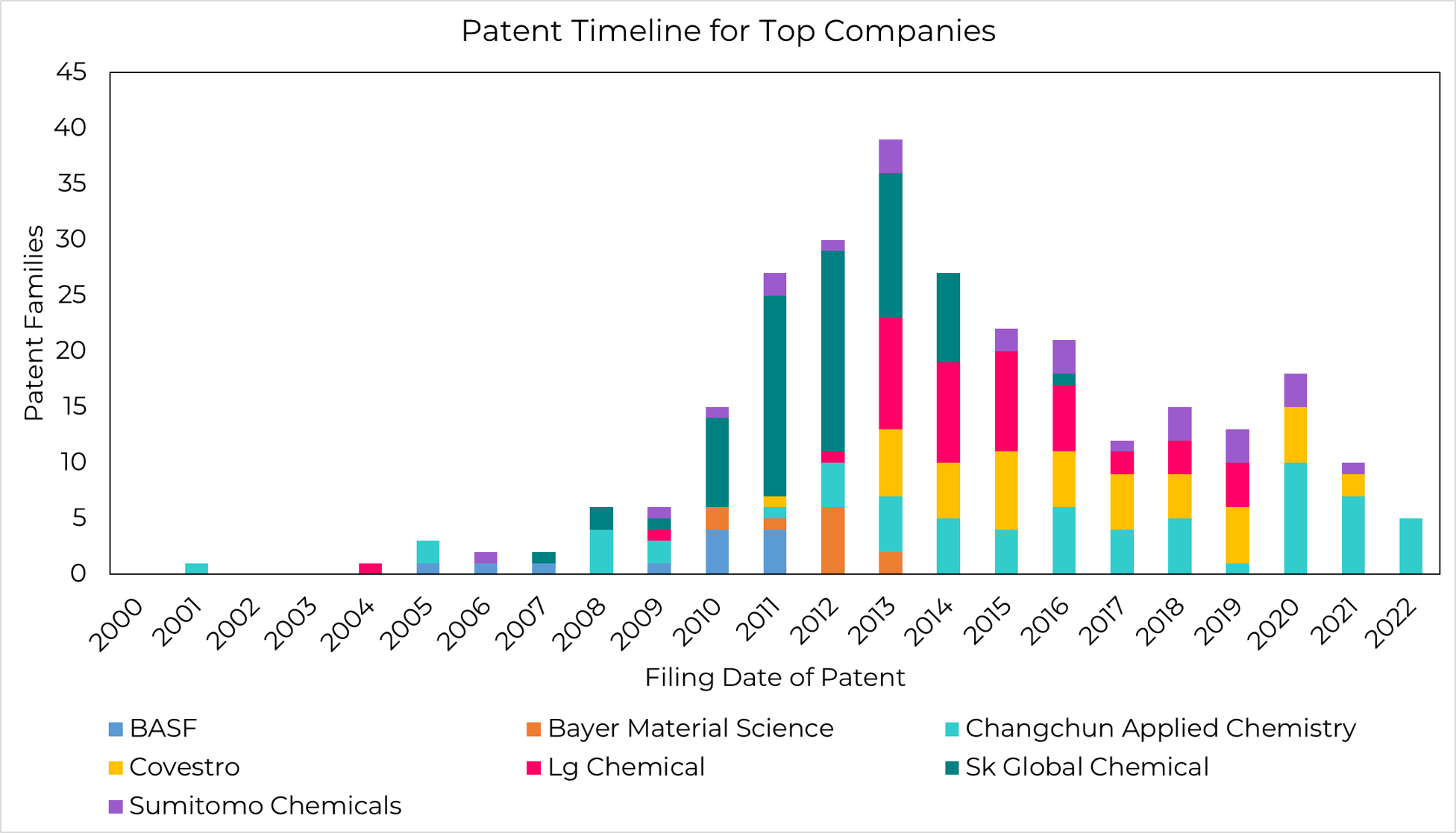

Based on BattScout's patent analysis, there are about a hundred patents today compared with ten patents in 2006. LG Chemical LTD is also one of the leading companies in patent registration for plastic production from carbon dioxide. In particular, the company developed essential catalysts such as polyolefin elastomers and carbon nanotubes and continued research and development on novel materials.

During 2011-2014, patents in this subject reached their highest level. In these years, Sk Global Chemical has registered the most patents. However, the company has reduced its R&D activities since 2014. Also, since 2013, four top patent owners, LG Chemical, Bayer Material Science, Changchun Applied Chemistry, and Sumitomo Chemicals, have followed a steady trend in the number of newly filed patents. To reach the 2050 climate goals, an estimated 7.6 billion tons of greenhouse gas emissions must be eliminated. Consequently, many companies are looking for ways to capture carbon from the atmosphere. However, Some big players, such as SK, are also exiting the market for these services due to their risks.