Tesla's New Recycling Method Reduces Cost and Water Waste

Tesla announced last year that it is developing a unique recycling method that can save up to 92 percent of lithium-ion battery materials. In 2020, the process recycled 1300 tons of nickel, 400 tons of copper, and 80 tons of cobalt. However, no details were revealed about its technology. According to Tesla's published patents, this article describes the technology behind its recycling process for the first time.

A standard method for recycling battery waste materials is hydrometallurgy. Argonne national laboratory has developed another unconventional method for recovering battery raw materials, direct recycling.

Another unconventional way mainly developed by Argonne national laboratory, direct recycling, is used to reobtain battery raw materials. A detailed introduction of these methods was published previously by Battscout. Acid leaching in hydrometallurgy uses significant amounts of water. Furthermore, a considerable amount of energy is required to separate byproducts in effluents such as ammonia, sodium sulfate, and solid particles before being released into the environment. These byproducts have no added value and industrial use. This process produces nickel and cobalt sulfates which are used to synthesize cathode material using wet chemical methods like co-precipitation. So the cathode production needs more water and results in more affluent.

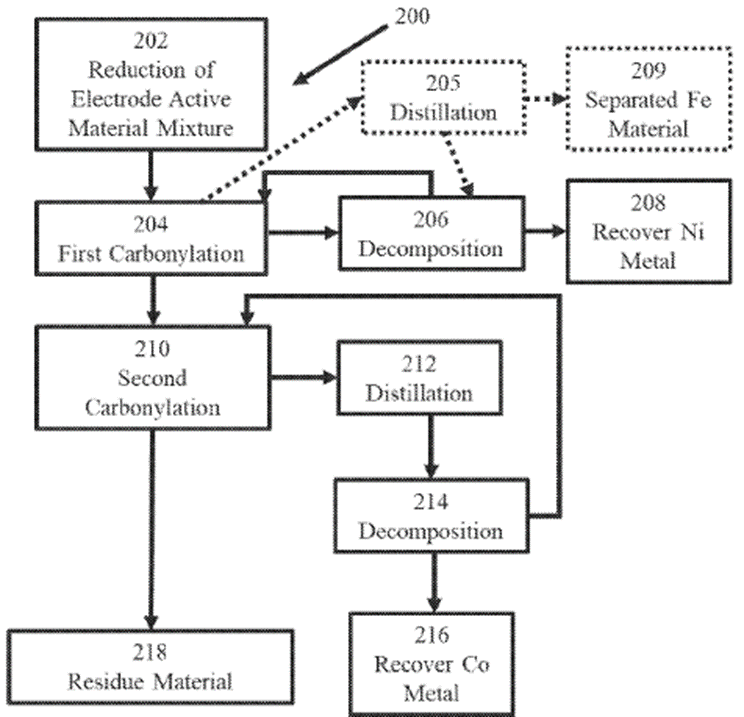

The "Mond Carbonyl Refining" process has been developed by Tesla to recycle waste material. Mond's method was firstly introduced in 1890 by Ludwig Mond. In this method, metal oxides are in contact with reducing gases such as carbon monoxide, producing metal carbonyls like nickel tetracarbonyl and Ni(CO)4. This metallorganic volatile gas moves to another chamber where the gas decomposes and pure metal precipitates. The separation of refined nickel and cobalt occurs as a result of multiple steps of decomposition at different temperatures. Tesla plans to use a new procedure for manufacturing cathodes by using metallic nickel and cobalt instead of sulfates in some cathode synthesis methods. With the Mond process, this environmental footprint is created, and the cost of recycling reduces.

The flowchart of the recycling process reported in Tesla's patent